Polystyrene (PS) is an artificial smelly hydrocarbon polymer made from the monomer known as styrene. Polystyrene can be solid or foamed and general-purpose polystyrene is transparent, rigid, and rather brittle. It is a cheap resin per unit weight.

Chemical formula: (C8H8)n

Melting point: ~ 240 °C (464 °F; 513 K) For Isotactic Polystyrene.

It is broadly employed in the food-service industry as rigid trays. polystyrene has several thermoplastics.

Let’s learn what is Polystyrene Resin, its Definition, Properties, Function, History, Types, Advantages, Disadvantages, and the difference between Epoxy Resin and Polystyrene Resin.

What is Polystyrene Resin?

PS plastic is generally used in a variety of consumer product applications.

Polystyrene is mostly useful because it has an application as foam. At Creative Mechanisms, we have used Polystyrene in several applications across a range of industries. It’s inexpensive and readily available. It is white in color, and it glues, sands, cuts, and paints well. The “S” in ABS is Styrene.

Properties of Polystyrene

Unadapted polystyrene is clear, stiff, brittle, and moderately strong. Its electrical properties are better though it has relatively low heat resistance.

Polystyrene is a different thermoplastic that is available in a broad range of formulations. The range of properties available along with the ease of processing makes polystyrene a good choice for many applied resistance.

It is impermeable to most foods, drinks, and household fluids. It is rigid, fragile, relatively hard, and has excellent gamma radiation resistance.

The cellular formation of expanded polystyrene makes it dimensionally stable. Therefore it does not deteriorate with age. A study undertaken in Norway monitoring the effects of time on the performance of PS has concluded that no deficiency effects are to be expected from EPS files placed in.

The Function of Polystyrene Resin

The functions of polystyrene resin are:

- As a stiff, solid plastic, it is often used in food packaging.

- When accumulating with different colorants, additives, or other plastics, polystyrene is used to make appliances, electronics, automobile parts, toys, gardening pots and equipment, and more.

- Polystyrene is used in refrigerators, air conditioners, ovens, microwaves, vacuum cleaners, and blenders.

- Polystyrene is used for housing and other parts for televisions, computers, and all types of IT appliances.

- Polystyrene food service packaging keeps food fresh for a longer duration of time.

- As it has clarity and ease of disinfection, polystyrene is used for a broad range of medical applications. For example tissue culture trays, test tubes, Petri dishes, diagnostic components, etc.

History of Polystyrene Resin

Polystyrene was first discovered in 1839. It was found by Eduard Simon, an apothecary from Berlin. From storax, the resin of the Oriental sweetgum tree Liquidambar Orientalis. He distilled an oily substance, a monomer that he named styrol.

This in time led to the substance receiving its present name. But it was close to a century before its use was commercialized by the IG Farben Company. It generated a polymer that was stiff and colorless and could be cast into molds with very fine detail.

The foam version of polystyrene that many of us associate with the name was found by the Dow Chemical Company, which sells polystyrene products to the US. Its invention was another misfortune pliable because Dow employee Ray McIntire was attempting to develop an insulator by combining materials under compulsion.

At the event, he ended up creating foamDow trademarked this enlarged polystyrene (EPS) as Styrofoam, a material that could be framed easily. Because of its good impact resistance, flimsy and low cost, it became Broadly used as protective packaging for goods in transit.

Advantages of Polystyrene Resin

Polyurethane is Cheap, rigid, transparent, easy to mold, and has dimensional stability. It has good electrical properties, low dielectric loss, and excellent resistance to gamma. Its Polystyrene is often used in cost-effective packaging products since it has many benefits, including:

- Resistance to bacterial growth

- Resistance to moisture

- Lightweight

- Provides insulation

- Durable

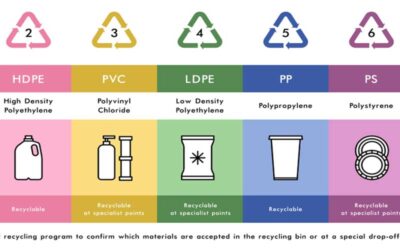

- Recyclable

Disadvantages of Polystyrene Resin

Polystyrene causes liver damage and nerve tissue damage. These effects can be mainly pronounced in fetuses and young children. Polystyrene products are made with petroleum, non-sustainable, and heavily polluting assets.

Extruded polystyrene is usually created with hydrochlorofluorocarbons blowing agents. It has several effects on ozone exhaustion and global warming. Their ozone depletion potential is reduced relative to chlorofluorocarbons which were formerly used.

But it still has 1000 times greater results on global warming than carbon dioxide. Burning polystyrene on bonfires frees Carbon Monoxide and styrene monomers into the environment. It is flammable. So it should be used carefully.

The degradation time of this product is long. It has poor resistance to organic solvents. Although recyclable it is unprofitable to do that.

Where to Buy Polystyrene Resin?

Check out the best polystyrene resin reviews to find the perfect one for yourself. And Visit the resin store to buy resins online at a cheap price.

Conclusion

Polystyrene resin is used for a wide variety of motives, and the professionals at Retlaw Industries manufacture products such as idler pulleys, adapters, and sprockets, all over the world.

It also offers good sterilized and insulation protection so it can be used in a wide diversity of applications from cups for hot drinks to the protection of food from damage.

I believe you have got a clear concept of the Polystyrene Resin Definition, Properties, Function, History, Types, Advantages, Disadvantages, and the difference between Epoxy Resin and Polystyrene Resin.

Read the pillar article to learn about all types of Resin Definitions, History, Types, Functions, Advantages, Disadvantages, and FAQ.