Adhesive resin is a carboxylic acid-based precursor plastic compound used to create polymers and adhesives for a variety of applications, including dental work, pressed building board compounds, and regular household glues.

Acrylic or diacrylate resin is the foundation for adhesive resin types of cement, which also contain adhesive monomers that adhere effectively to metal substrates. If using adhesive resin types of cement to attach to ceramic, metal, or dental substrates, a separate primer may be necessary.

Numerous commercial self-adhesive resin types of cement feature adhesive components that do not require separate etchants and primers for bonding to dental, metal, or ceramic substrates.

Adhesive Resin Definition

Most individuals have encountered resin from numerous plants in its natural form. This viscous liquid, which acts as a layer of defense and protection for some trees, is now manufactured synthetically on a vast industrial scale to supply paints and industrial adhesives to the building and construction industries. Therefore, synthetic resin is a chemical (or polymer) that has been manufactured artificially and has the properties of solidifying and bonding.

Adhesive Resin History

A Swiss scientist quietly set the course of dental adhesive history. The first method of cementing acrylic resin to dentin was created in 1949 by Swiss chemist Oskar Hagger working for DeTrey/Amalgamated Dental Company. His Cavity Seal material was introduced in 1951 and used dentin (rather than enamel) as the initial substrate for bonding along with a chemical curing resin known as Sevitron.

However, until the middle of the 1950s, when the development of dental adhesives really took off, this discovery didn’t have much practical application. From the no-etch and total etch systems of the fourth and fifth generation dental adhesives to the sixth, seventh, and eighth generations of self-etch systems, these early first-generation discoveries paved the way for amazing advancements.

Adhesive Resin Advantage

One of the most popular adhesive resin examples is epoxy resin, which is well-known for being a sturdy, water- and chemical-resistant compound for the flooring and woodworking industries. Epoxy resins can be used to make coatings, adhesives, and plastics. There are many resin adhesive uses.

However, agglomerates that are excessively polymerized throughout the production process, particularly the filtration phase, frequently pose a threat to the quality of adhesive resins.

The Functions of Adhesive Resin Cement: Composition and Reaction

Glass filler and diacrylate resins with acidic and adhesive groups make up self-adhesive resin cement. Typically, they are self-curing, dual-cured resins that can be triggered by light. Self-adhesive resin cement often experiences a pH change during the setting, going from acidic (pH 2.1 to 2.3) to less acidic (pH 5.6 to 6.0).

The cement’s early acidity makes it self-etching. Although the clinical ramifications of the less acidic pH have not yet been proven, the cement may become more hydrolytically stable over time due to the change to a less acidic pH.

Qualities of Self-adhesive Resin Cement

- Self-adhesive resin cement exhibit the following qualities:

- Refrigeration could be necessary; preheat before using.

- Self-etching; no need for phosphoric acid or a unique primer.

- Dual-cured; may be self-cured or light-cured.

- Fluoride-releasing.

- Typically offered in all-purpose, translucent, and opaque colors.

Self-adhesive Resin Cement’s Types and, Characteristics

Self-adhesive resin cement has low to medium binding strengths to the tooth structure and other materials. It is used in the adhesive resin dental industry. It is not advised to employ a bonding agent separately. Self-adhesive epoxy resin cement and bonding agents may be compatible, but using them just complicates manipulation and does little to strengthen the contact between the cement and the tooth. Higher bond strength can be attained with esthetic and adhesive resin cement that is bonded with different bonding agents or primers. There are adhesives for resin models.

Self-adhesive resin cements indications are typically not as durable as adhesive and esthetic resin cement. When these cement are light-activated, their measured flexural strength and modulus are typically higher than when they are self-cured.

Self-adhesive Resin Cements Manipulation

Etching and priming are not necessary when using self-adhesive resin cement. Although encapsulated goods are also available, the majority of products are paste-paste systems with auto-mix dispensers. Self-adhesive resin cement should only be bonded to tooth structure in accordance with the manufacturer’s instructions.

The cementation of porcelain veneers, feldspathic or leucite ceramic restorations, or any other all-ceramic restoration that is contraindicated for cementing techniques is typically not advised.

As an alternative, they are advised for the cementation of all-ceramic inlays and Onlays, cast alloy crowns and bridges, ceramometal crowns and bridges, and high-strength ceramic crowns, bridges, inlays/Onlays, and posts (eg, cast metal, ceramic, fiber-reinforced resin).

Issues of Adhesive Composite Resin

The following clinical issues should be kept in mind while working with self-adhesive resin cements:

- Avoid over-drying the teeth; if necessary, wet them with water.

- A gel barrier is necessary for the full set of some cements

- When feasible, activate using light. When activated with light as opposed to self-curing, dual-cured cements often have greater flexural strength and bond strength.

- The ambient light may affect translucent blinds.

- After a few seconds of exposure to the curing light, extra cement is simple to remove, but if you wait too long, it becomes difficult to clean up.

- In situations when there is insufficient retention, self-adhesive cement is contraindicated.

- On exposed pulp or dentin that is close to the pulp, self-adhesive resin cement should NOT be used.

- For post-cementation, several products offer extension tips for the capsules.

- Never spin cement into a canal gap for post-cementation using a lentulo. Before inserting the post into the canal, apply cement to it.

- When making all-ceramic restorations, use a silane primer.

Adhesive vs Resin

Both resin and epoxy are adhesives that are frequently used in the building sector. They are also known as plastic adhesives and are used to join metal, glass, and plastic. In addition to being useful for manufacturing and engineering, they can also be utilized creatively, for maintenance and repair, construction, and handicraft.

These plastic adhesives are distinguished by their outstanding heat, impact, chemical, and insulating resistance as well as their robust bonding capabilities. These plastic adhesives are offered in glue gun cartridges, syringes, containers, and ready-to-use packs. You need to be aware of some of the characteristics of each type of glue before comparing two widely used plastic adhesives for different applications.

An adhesive called resin glue is offered in both liquid and powder form. While the liquid version of this type of glue is typically packed with a powdered catalyst, which you must add to the combination before usage, the powdered form can be easily combined with water. Resin glues require more time to cure—typically eight to ten hours.

The time it takes for the glue to dry decreases with increasing ambient temperature. Construction companies frequently use resin glue because it offers good bonding. This form of adhesive is perfect for use in woodworking applications since it takes longer to set, which is good for work that requires care and patience to complete. In addition to wood, resin glue can be applied on countertops, wall panels, and floor coatings.

Where to Buy Adhesive Resin?

Check out the best adhesive resin reviews to find the perfect one for yourself. And Visit the resin store to buy resins online at a cheap price.

FAQ

1. Which is the best material for use in the building sector?

Answer: Both resin and epoxy are adhesives that are frequently used in the building sector.

2. In which form can we get it?

Answer: An adhesive called resin glue is offered in both liquid and powder form.

3. Why would we use Self-adhesive resin?

Answer: Self-adhesive resin cement has low to medium binding strengths to the tooth structure and other materials. It is used in the adhesive resin dental industry.

4. Which one is better between epoxy and adhesive?

Answer: One of the most popular adhesive resin examples is epoxy resin, which is well-known for being a sturdy, water- and chemical-resistant compound for the flooring and woodworking industries. Epoxy resins can be used to make coatings, adhesives, and plastics. There are many resin adhesive uses.

Final Words

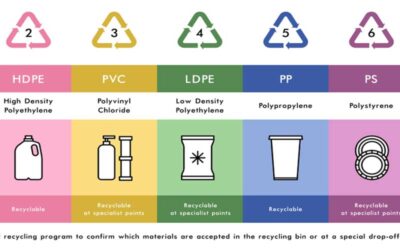

Since adhesive cement compounds are stronger than ordinary resins and adhere well to a variety of frequently used polymers, including nylon, polystyrene, and polycarbonate, they have a wide range of applications. Adhesive cement is used in automotive parts like plastic gas tanks, valves, and fittings because it adheres well to steel and aluminum components. Because of its powerful ability to bind to challenging materials, such as glass, and to metal film coatings on plastic in temperature-sensitive applications, terpene phenolics are a kind of adhesive resin that is employed in both automotive and packaging applications.

Read the pillar article to learn about all types of Resin Definitions, History, Types, Functions, Advantages, Disadvantages, and FAQ.