Synthetic resin, often known as resin, is a high-molecular-weight polymer created artificially. As a result, various plastic kinds can be identified by the name of the synthetic resin that they are made of.

Plastic’s primary raw material, synthetic resin, makes up 30 to 60 percent or more of its composition. It serves the purpose of agglutination, tightly attaching both the other materials and themselves together. The physical and mechanical qualities of plastic alter along with the type, characteristics, and quantity of synthetic resin. The fundamental characteristics of plastic, therefore, depend on the synthetic resin used to make it.

Synthetic Resin Definition

Synthetic resin is an organic molecule created by fusing carbon, hydrogen, a small amount of oxygen, and sulfur atoms together through certain chemical bonds. The molecular structure of synthetic resin is divided into three geometric shapes based on the many ways that carbon atoms combine in molecules: line type, branched-chain type, and somatotype (also called reticular type).

Synthetic Resin History

Stout and Cross (1937) made one of the earliest attempts to evaluate surface coatings for paintings. They looked at different coatings and compared their merits in terms of transparency, permeability, cohesiveness, flexibility, and solubility.

Dr. Robert L. Feller was appointed by the National Gallery of Art in Washington, D.C., to the recently created Fellowship on Artists’ Materials at the Mellon Institute in 1950. There, he started a thorough investigation into varnish properties and technology and published the findings of the first extensive testing on the physical properties of both the readily available synthetics and the natural resins damar and mastic (Feller, Stolow, and Jones 1985).

His findings made it possible to compare the different resins based on three fundamental characteristics: solubility, viscosity level, and hardness. Feller created the concepts of “viscosity grade,” which measures the viscosity in centipoises of a 20-weight percent solution of a resin in toluene at 70° F, and “solubility grade,” which measures the relative tendency of a resin to dissolve in hydrocarbon solvents (Feller, Stolow, and Jones 1985).

Despite the lack of a theoretical foundation for the concentrations chosen, toluene provided a convenient way to assess the relative solubility and viscosity of resins. Measurements of film flexibility were systematized by bending films cast on aluminum foil around mandrels of various diameters in addition to data on both Sward and pencil hardness (Feller, Stolow, and Jones 1985). Several years later, at the Metropolitan Museum of Art, gel permeation chromatography of various conventional and contemporary varnish materials served to confirm and establish the molecular weights of some and to establish them for others.

Types and List of Synthetic Resin

Polyaddition resin and polycondensate resin are two different types of synthetic resin based on the different synthetic processes used during manufacture.

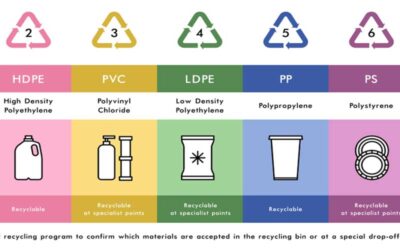

By using an initiator to break the unsaturated double bond of a monomeric chemical and then joining it once more in a covalent bond, polyaddition resin, also known as polymerized resin, is created. Polyethylene (PE), polyvinyl chloride (PVC), polystyrene (PS), polyvinyl acetate (PVAC), polypropylene (PP), polymethacrylic acid (PMMA), acrylonitrile butadiene styrene (ABS), and others are examples of common polyaddition resins.

Condensation resin, also known as polycondensate resin, is created by joining two or three different monomeric chemicals in functional groups. After being heated or catalyzed, this combination eliminates the tiny molecules. Phenolic resin (PF), urea-formaldehyde resin (UF), epoxy resin (EP), unsaturated polyester (UP), polyurethane resin (PU), and silicone resin are among the popular polycondensate resins (SI).

Synthetic Resin Adhesive Advantage

A chemical organic substance known as the synthetic resin is mostly made up of atoms like carbon, hydrogen, liquid synthetic resin, and a little amount of oxygen, nitrogen, and sulfur, among others, joined by specific chemical bonds. The primary ingredient in plastic is a synthetic resin, which serves as a bonding agent. It securely and tightly attaches other materials to itself in addition to its own structure.

What is Synthetic Resin?

Prepolymers (oligomers) or polymers made from petrochemically generated raw ingredients make up synthetic adhesives. To evenly distribute and wet the surface of wood, adhesives must be applied in liquid form. Prepolymers for adhesives can be used directly if they are liquids or as solutions, typically water solutions. Adhesive prepolymers cure by further oligomer reaction to produce polymers on-site. A cross-linking agent or catalyst addition and heat application are frequently used to speed up the curing activities.

Synthetic Resin Adhesive Functions

Although most people associate synthetic resins with plastics, they also have a usage in the production of surface coatings, glues, synthetic textile fibers, etc.

Synthetic Resin Adhesive for Paper

Artificial Resin Chemical joining is another name for adhesive bonding. Materials called synthetic resins have characteristics similar to those of typical plant resins. They are substantial fluids that can always solidify. They are completely different from the resinous mixtures that plants emit because they are synthetic.

Synthetic Resin Adhesive for Wood

Synthetic resin glue is made for use with porous surfaces, such as those found in woodworking and other materials. Wood, plywood, laminate, veneers, MDF, and all sorts of boards, as well as cork, are all securely bound by SH. But you must follow certain synthetic resin methods.

Resin is still the most important ingredient that affects the characteristics and principal applications of plastic. Plastics are created by mixing resin with fillers and additives that appear to modify plastic.

Synthetic Resin Uses

Synthetic resin glue is made for use with porous surfaces, such as those found in woodworking and other materials. Wood, plywood, laminate, veneers, MDF, and all sorts of boards, as well as cork, are all securely bound by SH.

The usage of synthetic resins is a technique for eradicating water’s enduring hardness. In this process, NaCl is used to convert the ion exchange resin (RSO3H) into RNA. Hard water is then softened as a result of the exchange of Na+ ions with Ca2+ and Mg2+ ions found in the hard water.

Where to Buy Synthetic Resin?

Check out the best synthetic resin reviews to find the perfect one for yourself. And Visit the resin store to buy resins online at a cheap price.

Final Words

Plastics, paints, and varnishes are just a few examples of the many items that use synthetic resins. Because of their improved durability, paints and varnishes made with synthetic resins offer better long-term corrosion protection of metal substrates.

FAQ

1. When to use synthetic resin?

Answer: The usage of synthetic resins is a technique for eradicating water’s enduring hardness.

2. Where can I use Synthetic resin?

Answer: Plastics, paints, and varnishes are just a few examples of the many items that use synthetic resins.

3. Which one is the best among plastic and synthetic resin?

Answer: Resin is still the most important ingredient that affects the characteristics and principal applications of plastic. Plastics are created by mixing resin with fillers and additives that appear to modify plastic.

4. What is the best place to buy synthetic resin?

Answer: Check out the best synthetic resin reviews to find the perfect one for yourself. And Visit the resin store to buy resins online at a cheap price.

Read the pillar article to learn about all types of Resin Definitions, History, Types, Functions, Advantages, Disadvantages, and FAQ.