Chemical substances with a molecular weight of more than 300 are known as resins. Natural resins can be divided into spirit-soluble and oil-soluble categories. Oil-soluble resins include rosin, which is extracted from long-leaf pine turpentine and used in a variety of processes, including soap making; copals, which are used in varnishes; amber; oriental lacquer, which comes from a Chinese tree; and cashew-nutshell oil. Rosin is the toughest natural resin used in jewelry.

Many different materials are used as Different types of resin. Sources can be both natural and artificial. Polymers, monomers, oils, fatty acids, and natural sources can all be used to make resins.

Different Types of Resin

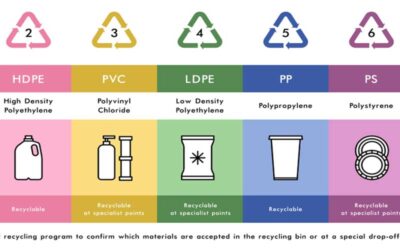

There are various types of resin such as Polyamide, Polyester, Polypropylene, Phenolic, Polyethylene, Polycarbonate, Epoxy, Acrylic, Silicone, Polyurethane, Polystyrene, Alkyd, etc. Also, types of resin incense, types of resin for 3d printing, fiberglass, water softener, art, casting, crafts, composite, wood, genshin impact, jewelry, cements, bonded bridges, and so on.

1. Thermoplastic Resins

A material that softens when heated and then hardens again when cooled. a thermoplastic item. Certain synthetic or semi-synthetic materials that can be shaped or extruded into objects, films, filaments, or utilized to create coatings and adhesives are referred to by this product-generic name. Both liquid and solid forms of TPA resin, as it is more widely known, are available. These are utilized in both aerosols and plastic coatings.

Eg: Polyethylene, Polyvinyl chloride, Polypropylene, and Chlorinated rubber.

Let’s examine some of the thermoplastic resins in more detail.

1.1 Alkyd Resins

Alkyd resins are created by combining polyhydric alcohol and polybasic acids and heating them. They have excellent chemical resistance, high electrical and thermal characteristics, and good thermal conductivity. Used for electric components, paints, and putty filers, it is quite affordable.

Alkyd resins, thermoplastic polyester resins, are created by heating polyhydric alcohols with polybasic acids. They have great electrical and thermal properties and are very good at blocking contaminants. They are inexpensive and are used for electrical protection, electronic components, clay fillers, and paints.

1.2 Polycarbonate Resins

Bisphenol A and phosgene are typically used to make polycarbonate resins. Having a high refractive index, resistance to filtration and staining, as well as electrical and thermal stability. They are employed as metal substitutes, lenses, safety helmets, insulators, and photographic film due to their inherent advantages.

Bisphenol A and phosgene are primarily used in the production of polycarbonate resins, which are thermoplastics. They are resistant to filtration, electrical and heated dimensional dependability, staining, and have a high refractive index. They are used as metal substitutes, protective coverings, focus points, electrical components, and photographic film.

1.3 Polypropylene Resins

These thermoplastic polymer resins are made of polypropylene, which doesn’t contain BPA. They have no flavor, no color, excellent heat resistance, and low density. They are utilized for toys, pipes, factories, and coatings and have excellent chemical resistance.

The most well-known type of resin is polyethylene resin, which is delivered in quantities of more than 100 million tons annually. They have a substantial degree of adaptability, a solid material, and a dampness or steam blockage. In addition to coverings and movies, compartments, link protection, coatings, toys, molds, linings, lines, and cylinders are all things that they are used to package.

2. Thermosetting Resins

Raw, unformed polymers known as thermoplastics and thermoplastic resins change from a liquid to a solid when heated or chilled. These enable two additional moldings, allowing for the reuse of parts and leftovers. TSA is used in conjunction with melamine resin to bake enamels, as is well understood. Automotive and two-wheeler coatings, e-rickshaw coatings, brass coatings, etc. are typical applications for industrial coatings.

Eg: Melamine, phenolic resins, Formaldehyde, Resins, Phenolic resins

Let’s take a closer look at a few thermosetting resins.

2.1 Phenolic Resins

Phenolic resins are a type of thermoplastic resin with great heat and impact resistance as well as resistance to chemical corrosion and moisture infiltration. They are utilized in a wide range of items, including cement glue, electrical components, molds, and brake linings. Thermosetting resins include phenolic resins. They have strong protection against artificial erosion and moisture infiltration and are sturdy, warm, and effect-safe. Machines can work with phenolic resins without any issues. They are used for brake linings, electrical components, overlay, concrete glues, reinforced cement, and forms. They are also used for resin impregnation.

2.2 Polyester Resins

Polyester resins are created when dibasic organic acids and polyhydric alcohols combine. The best thing about them is how well they can withstand heat and chemicals. They are widely utilized in building, fishing rods, decorative embellishments, coatings, and parts of ships and planes since they are relatively economical.

Polyhydric alcohols and dibasic natural acids react to form polyester resins. They are completely customizable and have excellent heat, synthetic, and fire resistance. They will typically be inexpensive. They are used for the creation, covering, and automatic repair of fillers, skis, casting poles, aircraft and boat parts, coatings, decorative extras, and containers.

Under 500 lbs. per square inch can be supported by a polyester resin.

Polyester is better suited for temporary modifications or uses that involve little tension. Due to its cheaper price, the resin has a greater reputation in the specialized and gem-making industries. In any case, remember that you get what you pay for. Polyester resin can break without any issues, offers little resistance to moisture, and is thought to be water-permeable.

2.3 Epoxy Resins

These polymers and reactive prepolymers are a subset of the epoxide group. They are very heat and chemical resistant, and they have good adhesive qualities. largely used in linings, propellers, surface coatings, and laminates. Polyepoxides also referred to as epoxy resin, are a class of reactive prepolymers and polymers that contain epoxide groups. They feature outstanding warmth and synthetic obstructiveness, as well as strong attachment characteristics. They are used for flooring, linings, propellers, overlays, glues, and surface coatings.

More Resin Types

There are a few more resin types:

1. Polyamide Resin

As a repeating element of their sub-atomic chains, amide bunches are present in polyamide resins. They are sturdy and safe, easily shaped, and light in weight. They are safe for scraped spots and substances and have a low coefficient of erosion. For non-lubricated heads, strands, gears, stitches, tires, watchbands, bundling, and jugs, are used.

2. Polyurethane Resin

Polyol and isocyanate segments make up the copolymers that make up polyurethane resins. They have a high degree of film adaptability and substrate bonding, and they are quite flexible when coupled with various gums. Additionally, polyurethane resins offer a good balance of hardness and flexibility. Elastomers, cement, and froth liners are used for dress and protection.

3. Silicone Resin

Sodium silicate and other chlorosilanes were once utilized to make silicone resins, but these days, the less elastic tetraethoxysilane or ethyl polysilicate and a few disiloxanes are widely employed. They are versatile, water resistant, and have excellent warm and oxidative security. Hard movies have a three-dimensional organizational structure similar to silicone pitches. They are used in applications requiring elastic, overlays, embodied pitches, defoamers, and water safety.

4. Acrylic Resin

Acrylic pitches are thermoplastic or thermosetting materials that are linked and formed from corrosive acrylic, corrosive methacrylic, or other comparable compounds. They have a respectable stiffness and are clear. Effective and UV-safe acrylic pitches are available. They serve as the foundation for and decoration for boards, cement, elastomers, coatings, signage, and transparent tiles.

5. Polystyrene Resin

Polystyrene resins are aromatic hydrocarbon polymers made from the styrene monomer. They are inexpensive, easy to make and provide excellent defense against salts, soluble bases, and acids. Additionally, polystyrene resins are very transparent and adaptable. They are used as protection, for pipelines, froths, cooling towers, elastic, dashboards, and car instrumentation.

Where to Buy Resin?

Visit the resin store to buy resins online at a cheap price.

Final Words

Different types of resin have the broadest range of uses. From paints and coatings to personal care and home care products, pharmaceuticals, rubber, plastics, and their coatings, the creation of electrical and jewelry goods, decorative items, wood coatings, etc.

In the modern industrial world, synthetic resins, which fall into two categories—thermoplastic resins, which stay plastic after heat treatment, and heat-setting resins, which become insoluble and heat-infusible—have largely supplanted natural resins.

Read the pillar article to learn about all types of Resin Definitions, History, Types, Functions, Advantages, Disadvantages, and FAQ.